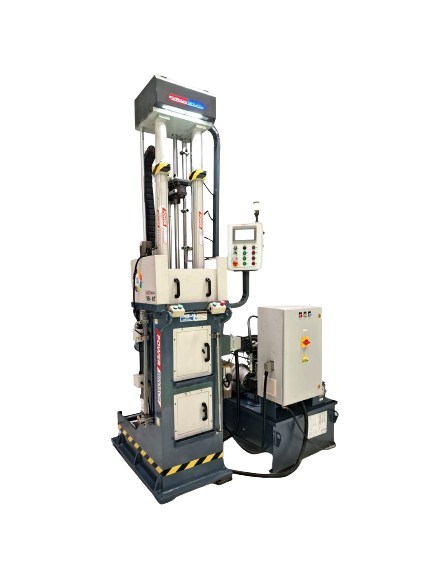

Vertical Internal Hydraulic Broaching Machine

Vertical Internal Hydraulic Broaching Machine

A Vertical Internal Hydraulic Broaching Machine is a precision machining tool used for cutting intricate internal shapes and profiles in metal workpieces.

This type of machine operates vertically, meaning the broaching tool moves in a downward or upward direction. Powered by a hydraulic system, it provides consistent and high-pressure force, ensuring accurate and efficient material removal.

The machine is ideal for producing keyways, splines, and other complex internal geometries in components used in the automotive, aerospace, and manufacturing industries.

Its hydraulic mechanism allows for smooth and controlled broaching operations, enhancing the quality and precision of the finished product.

Hydraulic Internal Broaching Machine “Highlights”

- Automatic Broach Retriever cum Follower

- Hydraulic Oil Cooler (Optional)

- Dual Push Start Button For Operator Safety

- Power failure recovery ( Machine Start from same

- position where power fail

- Hard fixture bed plate

- Lubrication pump timer based

- Hydraulic Oil Cooler (Optional)

- Easily tool height adjustment

- Easily tool height adjustment

- Deep Chip carrier or easily removal

- Low power consumption

- Compact foot frame with high rigidity

- Two Puller carrier with machine

- Bed flash through coolant (optional)

- Broach auto cleaner (optional)

- magnetic chip conveyor (optional)

“VIKAS MODLE”

Vertical Broaching Machine

Broaching Force: 3 – 5 Ton

Broaching Stroke: 400 – 1000 mm

“VIKAS WIDE BED”

Vertical Broaching Machine

Broaching Force: 3 – 5 Ton

Broaching Stroke: 800 – 1000 mm

“ECO SERIES”

Vertical Broaching Machine

Broaching Force: 6 – 20 Ton

Broaching Stroke: 800 – 1600 mm

Hydraulic Internal Broaching Machine “ECO SERIES”

| Description | Capacity | COMET | COMET + | STAR | STAR + | GALAXY | GALAXY + | GALAXY+ + | NOVA | NOVA + |

|---|---|---|---|---|---|---|---|---|---|---|

| Pulling Force | KN | 60 | 60 | 100 | 100 | 160 | 160 | 160 | 200 | 200 |

| Maximum Stroke | mm | 800/1000 | 1000/1200 | 1200/1400 | 1400/1600 | 1300/1600 | 1400/1800 | 1600/2000 | 1400/1800 | 1600/2000 |

| Cutting Speed | m/min. | 1-5 | 1-5 | 1-5 | 1-5 | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 |

| Return Speed | m/min. | 8 | 8 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Bolster Hole Dia | mm. | 60 | 60 | 80 | 80 | 100 | 100 | 100 | 120 | 120 |

| Main Motor | Hp. | 7.5 | 7.5 | 10 | 10 | 20 | 20 | 20 | 25 | 25 |

| Coolant Motor | Lpm. | 40 | 40 | 63 | 63 | 100 | 100 | 100 | 100 | 100 |

ECO SERIES Note:

>>> Bolster Diameter may change as per requirement, >>> Tool stroke/ Tool length may change as per requirement, >>> Wide Bed available as per requirement

|  |  |

ECO SERIESVB-06T | ECO SERIES VB-16T | ECO SERIES VB-20T |

The VB-6T is an eco hydraulic internal broaching machine designed for efficient and precise internal shaping. It combines cost-effectiveness with reliable performance, making it ideal for various industrial applications | The VB-16T is an eco hydraulic internal broaching machine designed for precision and efficiency. It provides reliable performance at a cost-effective price, ideal for various industrial applications. | The VB-20T is an eco hydraulic internal broaching machine offering robust performance for precise internal shaping. It delivers cost-effective reliability and efficiency, suitable for various demanding industrial applications. |

|

|

|

Processing examples