SH – SERVO HYDRAULIC

Surface Hydraulic Broaching Machine

A Surface Hydraulic Broaching Machine is an industrial tool designed for machining precise flat surfaces on metal workpieces.

Operating in a vertical orientation, the broaching tool moves either downwards or upwards to remove material and shape the surface to the desired specifications.

This machine is powered by a hydraulic system, which delivers consistent and high-pressure force, ensuring efficient and accurate cutting.

It is commonly used in manufacturing sectors such as automotive and aerospace for creating slots, contours, and other surface features with high precision and smooth finishes.

The hydraulic operation provides controlled, reliable performance, making it an essential tool for producing high-quality machined surfaces.

Surface Broaching SH is 2X to 10X Faster than Milling, Grinding and any other Machine.

Surface Broaching Machine SH

Our Surface Broaching Machines SH are engineered to deliver exceptional accuracy and superior finish, catering to a wide range of industrial applications. Designed to handle various materials with ease, these machines are built to provide consistent results and enhance productivity.

These machines are perfect for applications requiring high precision and reliability. With their robust construction and advanced features, they ensure optimal performance, making them a trusted choice for industries worldwide.

Explore our Surface Broaching Machines SH and discover how they can meet your specific needs and improve your manufacturing processes.

SH – SERVO HYDRAULIC BROACHING MACHINE

Highlights

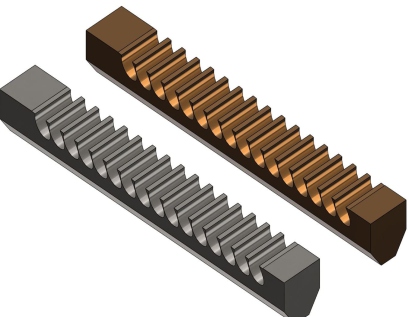

Broaching the surface of work pieces

Accurate positioning, high-speed broaching, high accuracy

Make complicated surface profile in one-pass

Heavy duty design, built to last 25 years, experience in fixture design

Touch Screen Human Machine Interface

Automatic Broach Retriever cum Follower

Hydraulic Oil Air Cooler

Tool Management Chart (48 Memory)

Tool Load Monitoring

Intelligent Machine Software PB GEN-5.1 (REF.PAGE-23)

Programmable Coolant Function

Dual Push Start Button For Operator Safety

Stepless broaching speed adjustment

Automatic loading/unloading devices are optional

CE specification based on requirement

Digitally height control

Key Specifications

Broaching Force: 2 – 50 Ton

Broaching Stroke: 400 – 2000 mm

| Description | Capacity | SB-6T SH | SB-10TSH | SB-16TSH | SB-20TSH | SB-25TSH | SB-30TSH | SB-40TSH | SB-50TSH |

|---|---|---|---|---|---|---|---|---|---|

| Pulling Force | KN | 60 | 100 | 160 | 200 | 250 | 300 | 400 | 500 |

| Maximum Stroke | mm | 400 | 800 | 1200 | 1600 | 1800 | 2000 | 2000 | 2000 |

| Cutting Speed | m/min. | 1-7 | 1-7 | 1-6 | 1-6 | 1-5 | 1-5 | 1-5 | 1-5 |

| Return Speed | m/min. | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Ram width | mm. | 150 | 250 | 350 | 380 | 430 | 450 | 550 | 550 |

| Main Motor | Hp. | 5 | 10 | 15 | 20 | 25 | 30 | 50 | 60 |

| Coolant Motor | Lpm. | 23 | 40 | 40 | 63 | 100 | 100 | 210 | 210 |

SH – SERVO HYDRAULIC

Note: Tool stroke/Tool length may change as per requirement

SH – SERVO HYDRAULIC BROACHING MACHINE

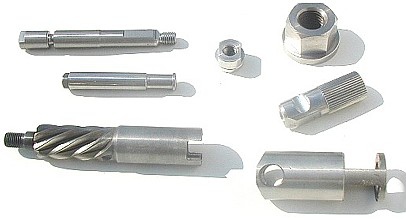

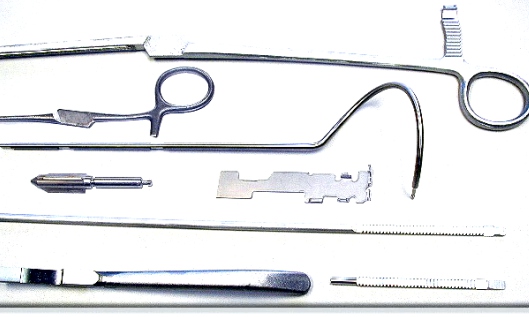

Processing examples